Now Reading: How are surfboards made? A beginner-friendly guide

-

01

How are surfboards made? A beginner-friendly guide

How are surfboards made? A beginner-friendly guide

My foamie had an unfortunate encounter with a couple of fins that exposed its insides. That made me think—we should talk about how the surfboards are made.

The most common modern surfboard is made using a polyurethane (PU) or expanded polystyrene (EPS) foam core with a fiberglass and resin shell. I have both, so this is gonna be interesting.

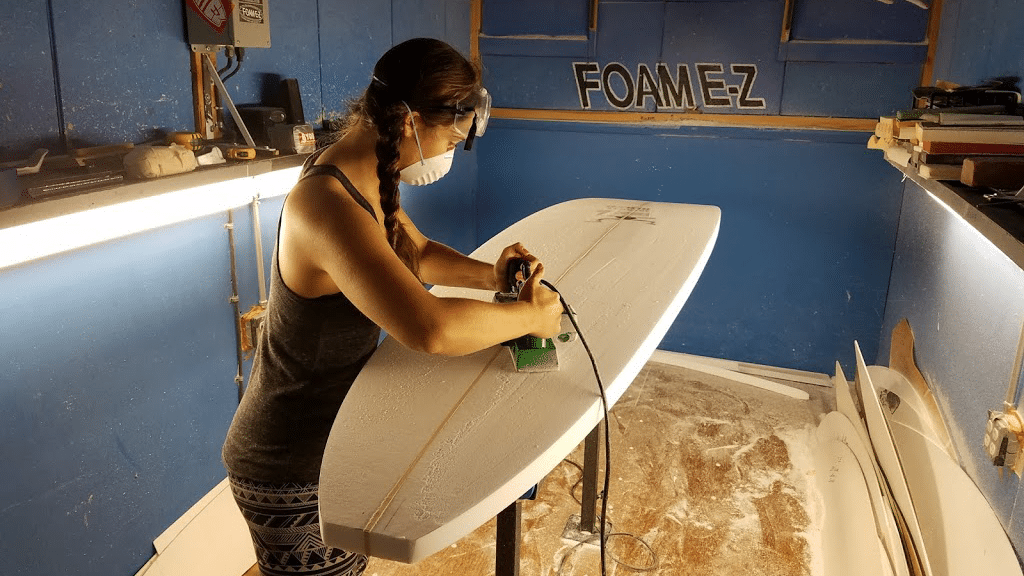

Polyurethane (PU) is a type of plastic that is lightweight and easy to shape by hand, and it’s been around since the 1950s. It’s compatible with polyester resin, which is fast-curing and easy to work with, Winners! Not quite. The foam is made using isocyanates and blowing agents, which can be hazardous during production. That’s why shaping PU blanks generates dust and fumes that need to be handled with masks and good ventilation.

Oh, and while PU boards work great, they’re not eco-friendly—they don’t break down easily and release VOCs (volatile organic compounds) during construction. Which is one of the main reasons, some surfers are now turning to EPS/epoxy boards and eco-friendly foams to reduce environmental impact.

PU vs EPS: what’s the difference?

I have to admit I didn’t fully understand all the differences between PU and EPS. Until now. It’s all to do with what the foam looks like inside. PU is closed and dense, EPS, bead-like and airier. As a result, PU is heavier and less buoyant for its volume, EPS can be 30-40% lighter, with more float for its volume. PU is more resistant to pressure dings, but cracks easier. EPS less so, but can be tougher when glassed correctly with epoxy.

The resulting boards offer different “feels”. What on earth is a feel??? It basically refers to how a board responds under your feet, especially when you turn, trim, or ride through choppy waters.

That’s why PU boards feel so smooth and more stable, like riding a bike with suspension, because a PU board when glassed absorbs vibration better. In turn, EPS foam is less dense, so it’s paired with epoxy resin, which is stiffer. This makes the board more responsive, which is why shortboards are EPS. When you, because definitely not me, pump down the line or turn hard, it feels like the board rebounds quickly—giving a sense of energy or pop.

Then, there’s “flex”, and that’s how much a board bends and rebounds under pressure (like when you bottom-turn for instance). The way it flexes and releases affects your speed, control, and flow. So, PU boards bend gently and recover smoothly, making it feel fluid or flowy under your feet. EPS boards spring back faster after bending, which can help generate speed—especially in small waves. OMG this explains so much!

From blank to board

Back to surfboard making.

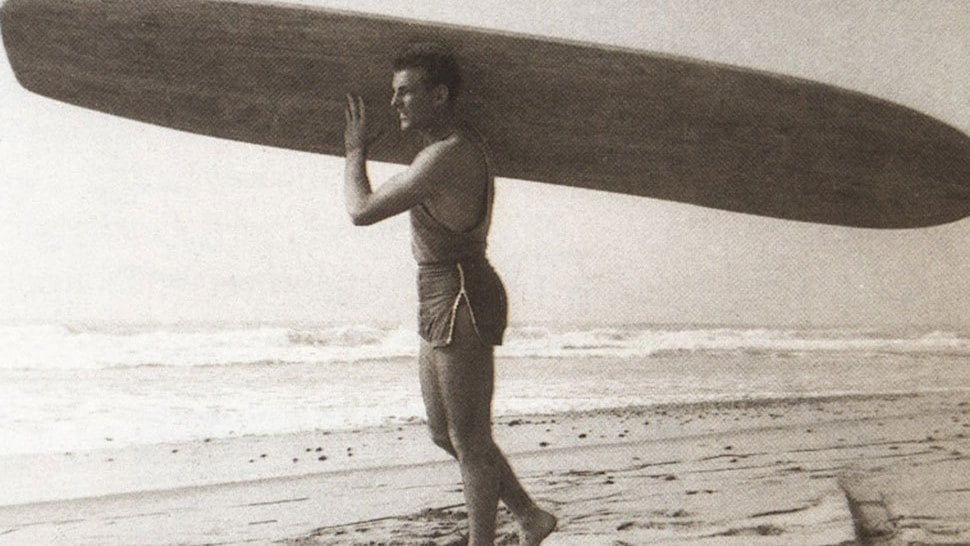

A surfboard shaper starts with a foam “blank”. These do not grow on trees. You need to get it from a specialized blank manufacturer. These guys, probably wearing Hazmat suits, pour and mold polyurethane (PU) or expanded polystyrene (EPS) foam into rough surfboard shapes that come in different sizes, thicknesses and rockers. We already talked about a rocker, but it’s curved shape of a surfboard from nose to tail.

So a shaper, takes such a blank, cuts and planes it to form the basic shape of the board (rocker, rails, width, etc). They can do it by hand using planers, rasps, and sanding tools—or with CNC machines for mass production.

Then, if it’s a PU board, a stringer (wooden strip) is glued into the center to add strength and flex control. It’s not that common, but not unheard of in EPS boards.

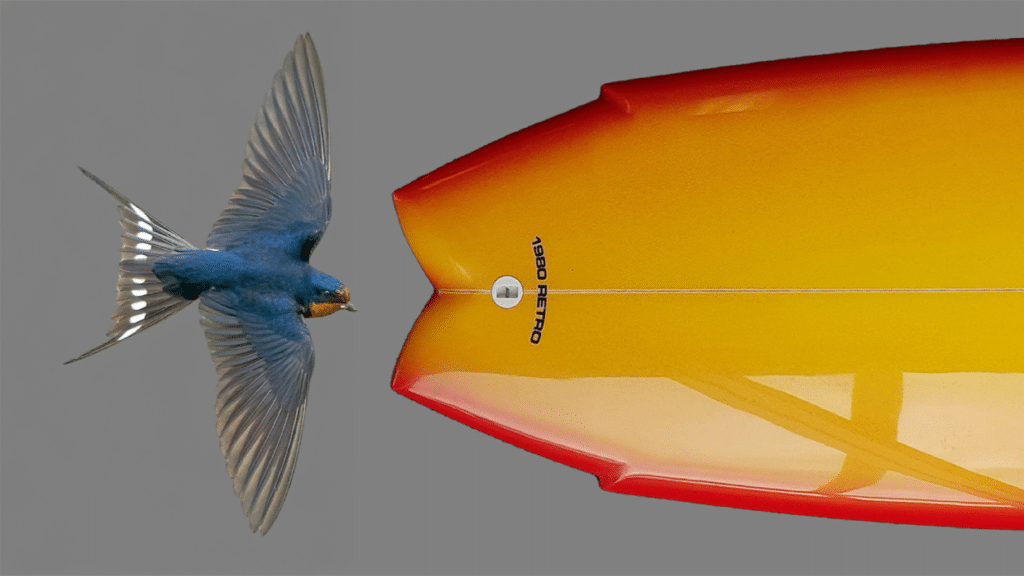

Final shaping follows that includes fine tuning of the rails, bottom contours, tail shape, nose shape. This stage effectively determines what sort of board it will be like, how it will behave in the water.

Then comes the laminating or glass layup. The board is covered in fiberglass cloth, usually one or more layers on top and bottom. Then, resin is applied. PU foam uses polyester resin, rarely epoxy resin. EPS foam uses epoxy resin (because polyester melts EPS). That’s why when you buy a ding kit, you should remember that you can use epoxy on both PU and EPS boards, but you can’t use poly on EPS.

Once the resin cures, a “hot coat” is applied—a smoother outer resin layer. Then the board is sanded down to a smooth finish.

The fin box goes in, and is glassed with resin, and a leash plug is installed near the tail. Finally, and it’s dealer’s choice boards can be painted, airbrushed, or left raw depending on design. Some are glossed and polished; others are left matte for weight savings.